Aluminum Flood Wall

What is Aluminum Flood Wall?

Aluminum Removable Flood Wall for water conservancy project is mainly used to elevate additional height to the existing insufficient flood protection height on the bank or dikes or RC foundations preventing the overflow of rivers and lakes or urban waterlogging. An effective protective high wall is erected by using the advantages of high strength and light weight brought by aluminum alloy materials. Compared with the disadvantages of traditional concrete water retaining wall, such as irreversibility, unsightness and direct blocking of residents' hydrophilicity, aluminum alloy protection system can make up for these requirements. There are many precedents in China. In the future, this kind of aluminum alloy flood wall with convenient disassembly and wide application range will be more popular.

Features:

1. Removable

2. Flexible assembly and disassembly, quick responding speed against flood

3. Offering extra flood protection to existing insufficient flood height

4. Customized product appearance (anodized, power coated, wood grain, marble grain)

5. Customized turning and cornering for required project protection line distribution

6. Without blocking the hydrophilicity of residents to the nature and not intrusion to the surrounding landscape engineering

7. Excellent flood control performance

8. Durable Design Life 20-40 years

9. Easy Maintenance

Specification:

Raw Material | Aluminum Extrusion & Stainless Steel, Gasket |

Length | Unlimited Length, in modules sections designed according to flood height request |

Height | H200-H5200mm by different models |

Panel Thickness | T35/50/70/100mm |

End Post | 130-170mm higher than panel stacking height |

Gasket | EPDM, PE |

Application | Elevation for extra flood protection height along river, lake or ocean, etc. |

Product Composition:

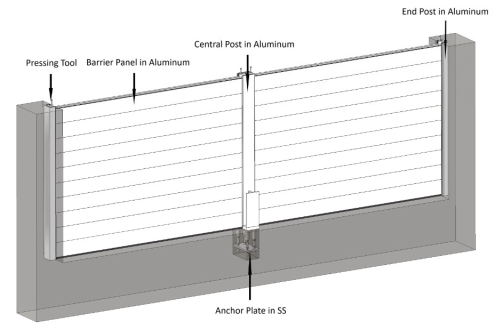

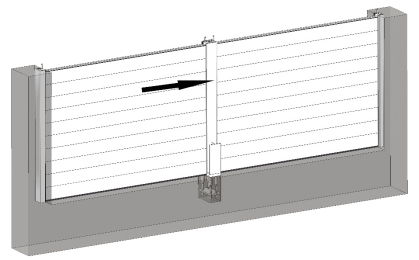

The product composition can be roughly divided into five parts: Posts (including End Post fixed to the wall, and Removable Central Post attached to the ground), barrier panels, embedding anchors, press-down claps and bolts and seals, as shown in the figure.

Please read the demo sketch of system break-down below by with Solidworks engineering.

The Sketch of Full System

End Post

The End Post is made of 6063 or 6060 aluminum alloy, after extrusion, aging, anodizing, welding and other fabrication steps. Anti-weathering EPDM gasket is installed inside the post to ensure the water tightness between the slot-in barrier panels and the posts. It is permanently installed on the current building’s wall in different fixing method designed after we study the site condition.

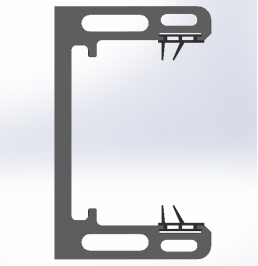

Removable Central Posts

Removable Central Posts are used to extend the unlimited length of the flood wall by splitting the wall into modules. And with customized angle, the wall can be achieved in turning and cornering.

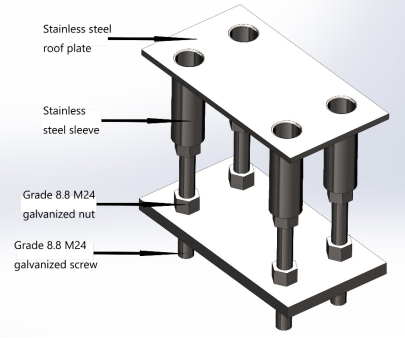

The main body of the Removable Central Posts is extruded by 6063 series and 6005 series aluminum alloy. After aging, the strength of the post is enhanced. It should go through other fabrication such as cutting, welding and anodizing, ect. Each central post can be divided into three parts, the extrusion profile of post, the bottom base and the reinforcing bracket which are machined and welded together. The welding method is extremely important as argon arc welding carried out by skilled welder with certification or auto welding robots, and each welding joint has three layers of welding to secure the strength. Together with the strength of the robust post extrusion profile, it bears the overall load generated by the flood water applied to the aluminum flood wall constructed. Anti-weathering EPDM gasket is installed inside the post to ensure the water tightness between the slot-in barrier panels and the posts. The central post is attached to the embedded anchors which is flush to ground with 8.8 Grade M24 galvanized bolts to ensure its safety and stability. After flood season, the central post can be removed and stored and there is no protrusion on the ground.

Barrier Panels

The barrier panels are made of 6063-T6 aluminum alloy, and the flood protection height of single piece is H200 mm. According to the flood protection design, they are available in thickness varies from 35/50/70/100 mm, with the extrusion profile thickness from 2.2 to 4.0 mm offering different strength together with the matching post after our design to achieve the flood protection requirement of customer. The internal structure is cavity to have water filled to increase its stability in active flood water. The panel top is equipped with anti-weathering EPDM gasket to ensure the water tightness between the panels and the lowest panel bottom has a customized EPDM or PE ground gasket to prevent leakage at system bottom.

Embedded Anchors

A complete Embedded Anchors consists of top plate in SS, sleeve in SS, fixing Bolts in GMS or SS, Protective Caps in SS and Mild Steel bottom plate. The top plate surface is generally flush to the ground surface after embedded, and the bottom plate with the adjustable nuts is welded to the steel grills in the reinforced concrete foundation. In dry season, SS protection caps can be used to keep the dust and debris into the thread of bolt holes.

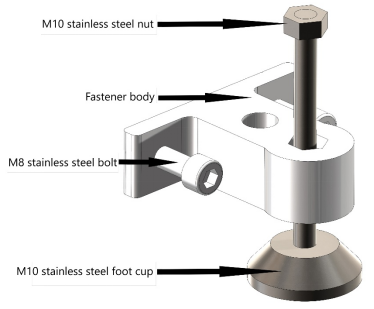

Press-down Tools

The Press-down Tool is a tool which generates downward compressing on the top of the barrier panels which has been stacked in place. The main material of Press-down Tool is aluminum alloy, or stainless steel. After the barrier panels stacked to the required height, The Press-down Tool will be fixed from the top of the posts ensure the water tightness at the interface between the lowest panel’s bottom gasket and ground.

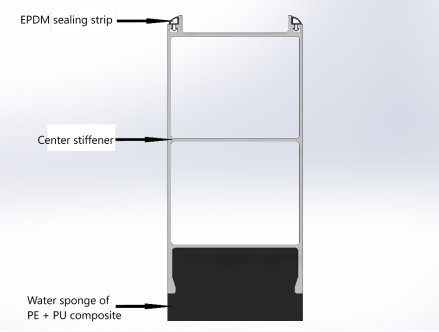

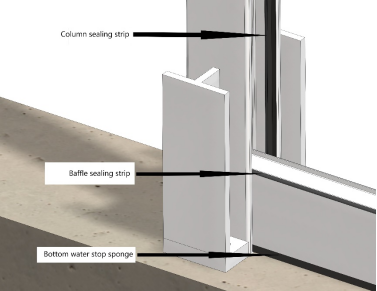

Gasket and Seals

The Gasket and Seals are to keep the system water tightness which should be flexible and anti-weathering. They include vertical in-post gasket, panel-inter gasket and ground gasket. The vertical in-post gasket, panel-inter gasket is made of EPDM the same material for door seal of vehicles, and the ground gasket is optional in either EPDM, Full PE or PE&PU Composite according to site ground condition depending on if compensating the unevenness of the ground is required, to effectively prevent the invasion of flood water at the system bottom.

The Sketch of Gasket and Seals